So I built up the bearing assemblies on the underside of the build plate - to approx the positions as per the drawing

According to the diagram the slide bar support center is 70mm from the inside edge of the frame, then 160mm between the centers and another 70 to the end of the bar (300mm in total) however the bar is 360mm in length, the build plate is 300mm long. Now for the build platform - and here I found a mistake in the instructions. The top and bottom rails here need to be 96mm apart.Īdding the additional brace - a 3D printed part. looking at the casting I could see a small burr.Ī quick hit with a file (no not a hammer) and 68mm spot on (well 67.98 - I can live with that). The two rails close together at the top need to be 68mm apart, the nearest I could get was 68.9mm. Unpacking the bits - we get lots of goodie bagsĪssembling up the first frame, the corner brackets are easy to fit and align So looks like Toto's mojo has headed north, and arrived at Dundee. Hopefully I will do this bit at the end of the build. The material thickness etc can all be setup in the software, and finally generate the cut file for the controller to use (the Gcode). etc in Inkscape, then export (or save as) as a DXF file and import that file into Artcam (provided with the cnc m/c). So you could design a house front, with brick courses, window and door apertures etc. Inkscape) can export DXF files, which can be imported into CAM packages to produce the Gcode. Hopefully it will machine Brass, according toi the specs it will machine wood, mdf, plywood, acrylics, alluminium, copper and soft metals - I'm hoping brass and nickel silver are soft enough - just need to adjust the depth of cut and speeds accordingly.Īs for the programs things have changed a lot, you no longer need to programme in Gcode (you can if you want and there plenty of tutorials on youtube to try). Next will be the assembly, but that will need to wait until tomorrow.

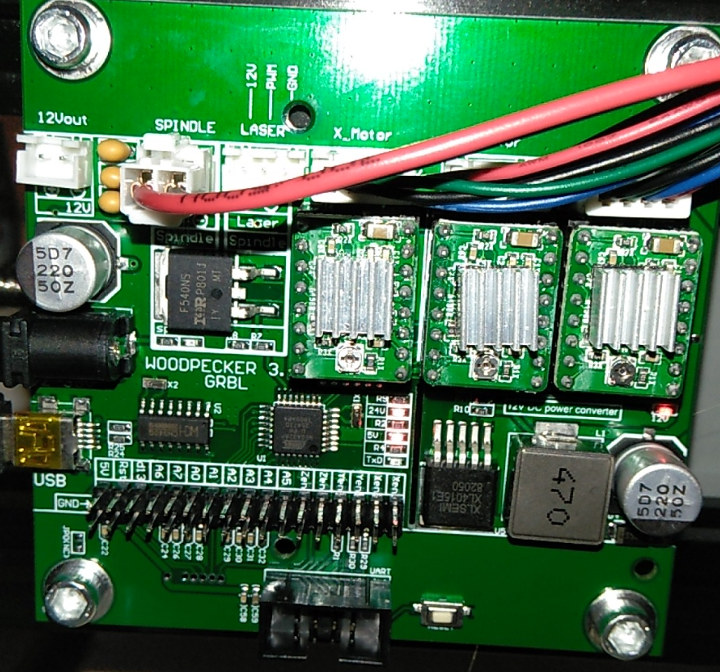

#Woodpecker 3.2 grbl software#

The software provided to control the CNC is Grbl Control.Īlso provided is Artcam - for creating Gcode instructions for Grbl Control, and CopperCam a PCB creation tool.

#Woodpecker 3.2 grbl code#

I'm impressed with the packaging everything is well protected and nothing rattles about.Ī link with a login code is provided to download the latest assembly instructions and software, although versions are provided on the CD. Removing these and a 25mm piece of foam gives the next bunch - support bars and brackets, screws and allen keys, adapter plugs for UK and EU some drive mounts and the controller board.Īnd the final layer gives the extruded alluminium frame bars, power supply, stepper motors for the X & Y axis, additional support brackets for the frame Z axis and the assembled spindle motor and Z axis unit. To get a usb cable, mains cable with a US 2 pin end, mini CD, and a build plate. Well here is what Santa's helpers dropped off. Just a taster - i'm still printing off the assembly instructions - actually just a set of drawings / pictures.

0 kommentar(er)

0 kommentar(er)